Data is power. The power to make informed decisions to maximise ROI, reduce costs and improve the efficiency of your fleet of heavy equipment.

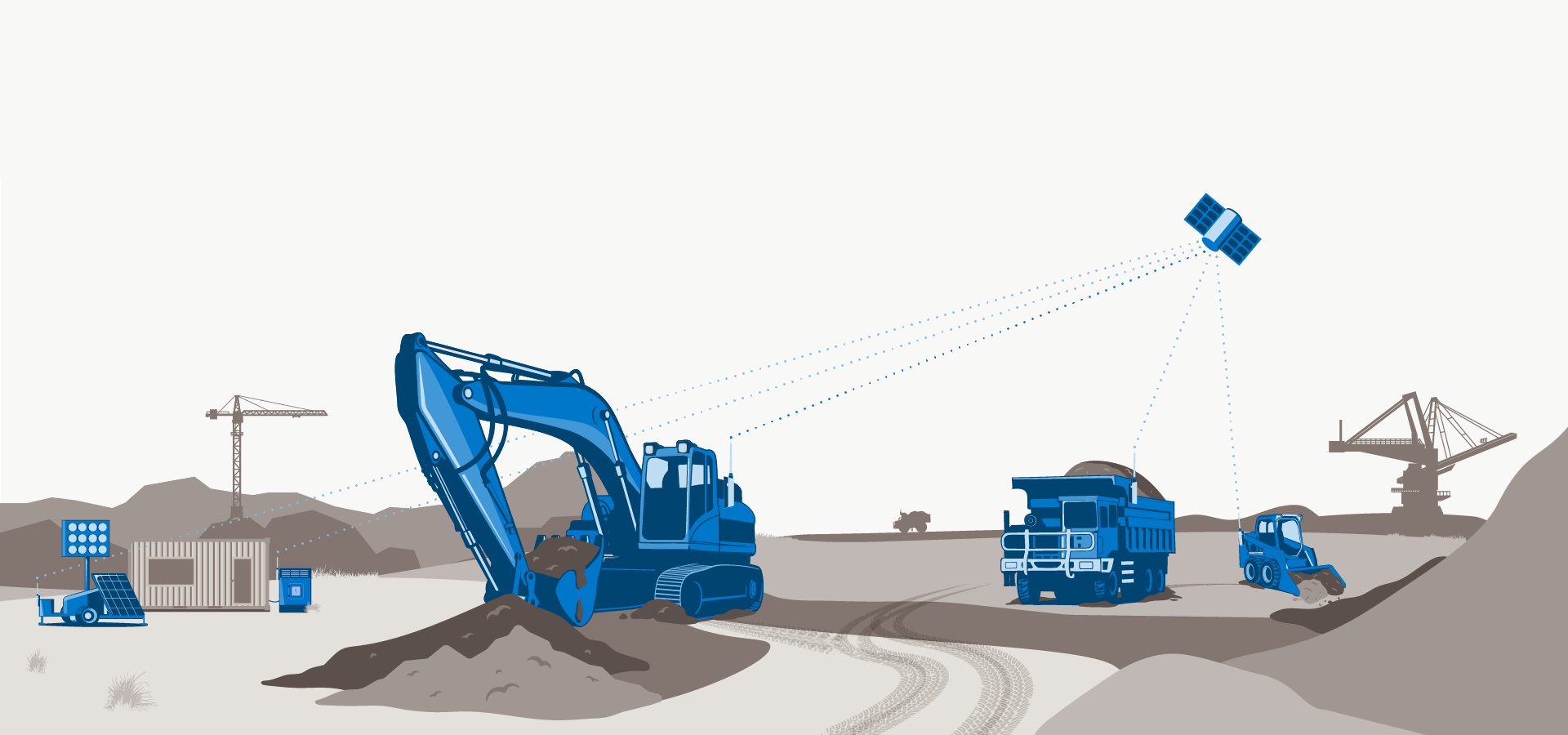

When operating outside metro areas means you can’t always rely on cellular connectivity to get the data you need. The result? Unplanned maintenance, difficult asset management, productivity loss, and stolen equipment near impossible to recover.

The scope of the problem is significant. In the United States alone, $1 billion is lost to theft, with recovery rates between 5% – 20%. The opportunity cost is also significant, with companies suffering 23% worst financial performance than competitors if less than 50% of their fleet is connected.

The Myriota Network provides reliable, consistent coverage independent of topography and cellular service areas – the bridge between human, machine, and operational efficiency gains.

In this webinar we deep dive into how remote, underutilised equipment can benefit from affordable, long-battery life connectivity via satellite.

The key takeaways:

-

The challenges that remote industries are facing

-

How global organisations benefit from IoT monitoring

-

The benefits of remote monitoring for worksites

-

How Myriota simplifies IoT connectivity from lab to field via low-earth orbit satellite

Get on-demand access

Myriota was an obvious choice as the leader in ultra-low power, satellite connectivity designed specifically for the internet of things. We wanted to build a tracker that could be retrofitted to powered and unpowered assets alike, and give reliable reporting even in remote areas like mine sites or across rural Australia.

Adam Schindhelm, CEO, INCYT

IoT connectivity to simplify product rollout and ongoing maintenance.

-

No job or location is too remote

Move beyond the barriers of location – connect anywhere with sky view to get complete control over your valuable assets.

-

Low-cost, long-battery life

Optimise operational efficiency to keep projects on track, on budget and save your bottom line. Simple to deploy – point your device to the sky. Simple to maintain – get years of battery life. No gateways, no towers, no fuss.

-

Reduce equipment downtime

Spot potential problems with predictive maintenance to optimise equipment usage for increased ROI.

-

Increase valuable asset utilisation

Prevent loss and theft, lengthy yard or job site hunts, and unnecessary and costly equipment transfers to and from job sites.

-

Support your journey towards sustainability

Reduce the impact of all aspects of equipment operation with insights for sustainable decision-making.

Trusted by governments and global brands

Ready to revolutionise your industry?

Unlock your potential